- Home

- >

- Recycling Flow

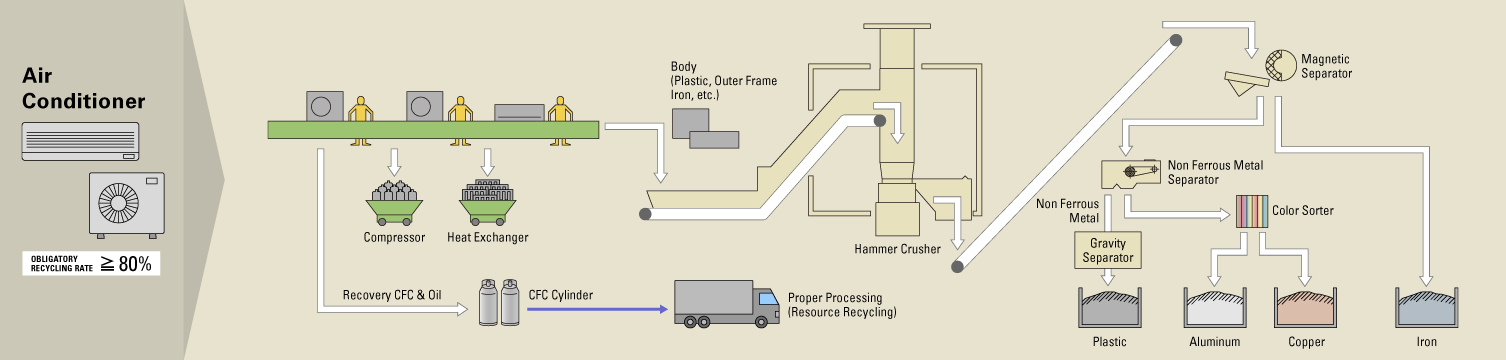

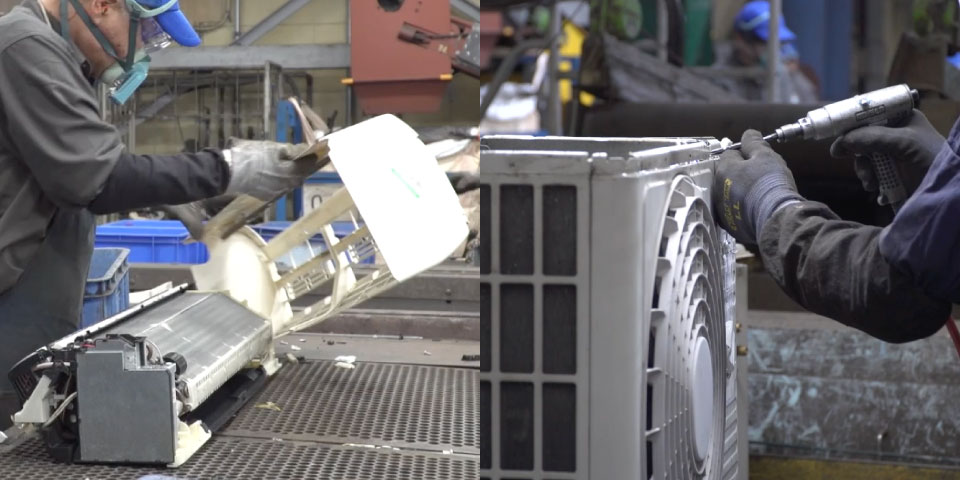

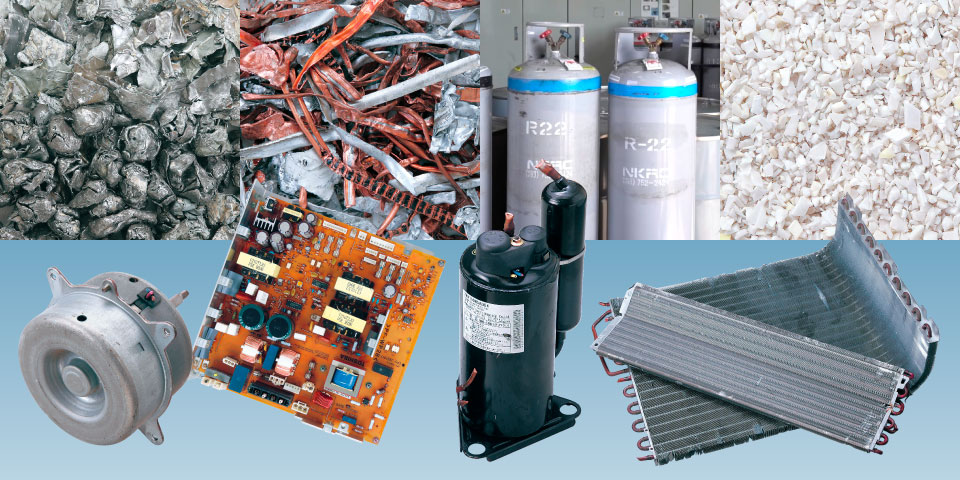

Recycling Flow: Air Conditioner

①Recover CFC. ②Collects compressor and heat exchanger. ③Put the disassembled body plastic, outer frame iron, etc. into a crusher. ④Recover iron, copper, aluminum, plastic, etc. by magnetic separation, non ferrous metal separation, color separation.

Points of recycling

Reliably recover CFC. The indoor unit and the outdoor unit are separately disassembled and the main parts are collected. Many metal parts such as iron, copper and aluminum are used in air conditioners. By accurately separating and collecting each material, it becomes a valuable resource. Those that are not recovered in the manual dismantling process are crushed by a machine and separated using the characteristics of the materials to increase the purity as a resource and recover them.

Main recovered resources

Manual dismantling process: CFC, Compressor, Heat Exchanger, Motor, etc.

Crushing / Separation process: Iron, Copper, Aluminum, Plastic, etc.

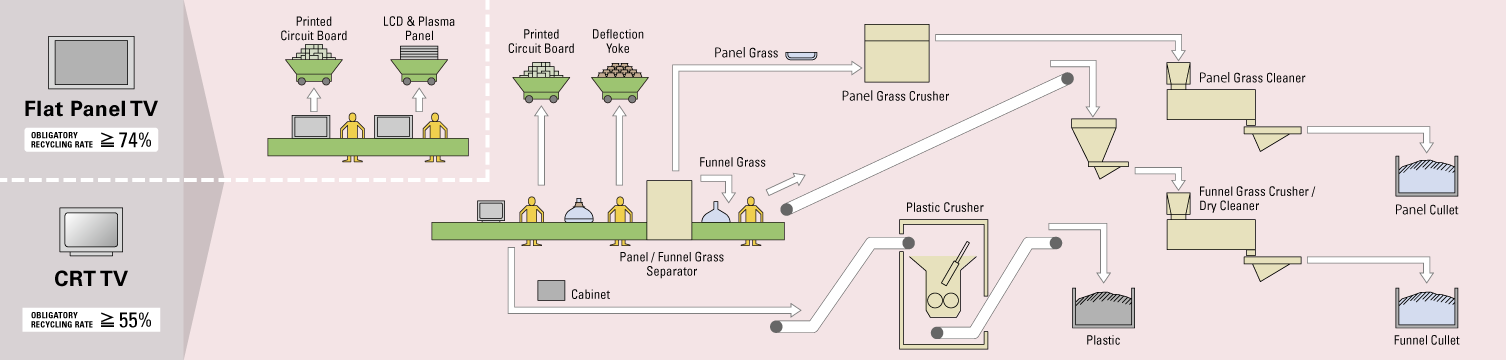

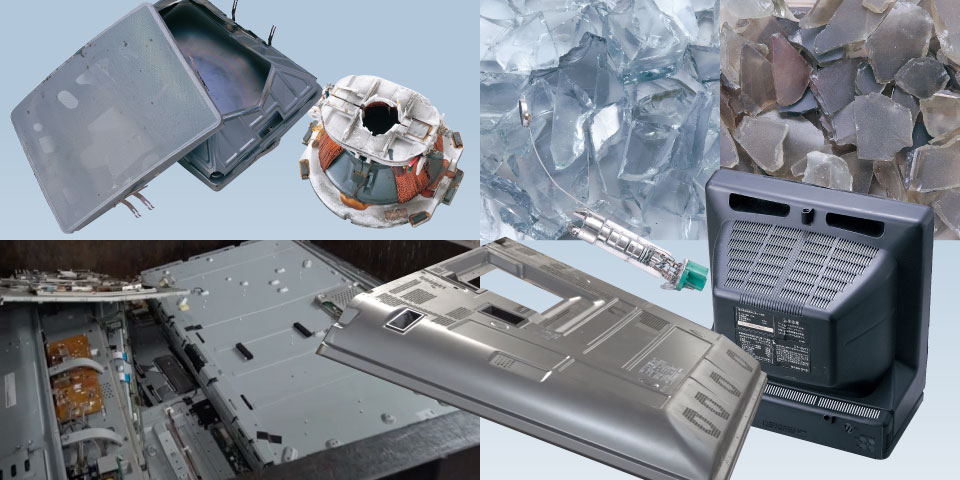

Recycling Flow: CRT TV / Flat Panel TV

Flat Panel TV: ①Separate and collect the LCD panel, plasma panel and printed circuit board. CRT TV: ①Dismantle and collect the back cabinet, printed circuit board and deflection yoke. ②Separate the cathode ray tube into a front panel glass and a rear funnel glass by heat rays. ③Crush and wash the panel glass and funnel glass and collect each as cullet. ④The back cabinet is also crushed and washed by another crusher and recovered as plastic.

Points of recycling

Since the structure of Flat Panel (LCD / Plasma) TV and CRT TV is very different, they are disassembled by separate lines. Mercury used in LCD TVs is also reliably recovered. CRT TV cathode ray tubes are separated and recovered according to the glass material.

Main recovered resources

CRT TV: Electronic Beam Gun, Deflection Yoke, Printed Circuit Board, Glass, Leaded Glass, Plastic, etc.

Flat Screen TV: Printed Circuit Board, LCD / Plasma Panel, Optical Sheet, Plastic, etc.

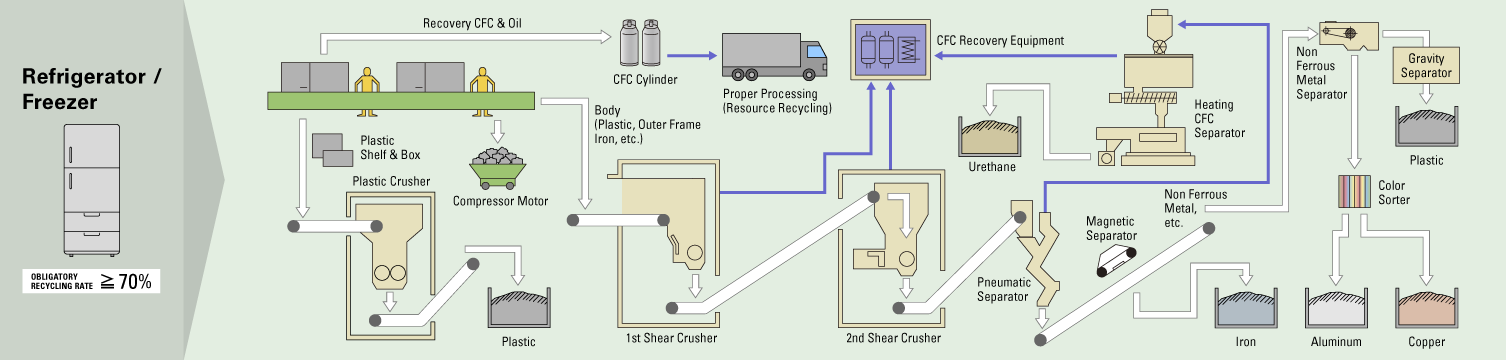

Recycling Flow: Refrigerator

①Recover CFC. ②Separate the compressor and motor from the body. ③Put the body, vegetable box, and food shelves into each crusher. ④Vegetable box and food shelves recovered as plastic. ⑤Insulation material urethane is separated and recovered as CFC and volume-reduced urethane by pneumatic separation and heating CFC separation. ⑥Other crushed materials are recovered as iron, copper, aluminum and various plastics by magnetic separation, color sorting, etc.

Points of recycling

Fluorocarbons contained in refrigerant CFCs and insulation urethane are reliably recovered. Single material plastics such as vegetable boxes and food shelves are crushed and collected as they are. About 60% of the total weight of a refrigerator is metal. After collecting the main parts by manual dismantling, the whole body is put into a crusher, and various metals are recovered through crushing by the machine and sorting using the characteristics of the material.

Main recovered resources

Manual dismantling process: CFC, Compressor, Motor, Plastic, etc.

Crushing / Separation process: Iron, Copper, Aluminum, Plastic, Volume-reduced Urethane (defluorocarbon), etc.

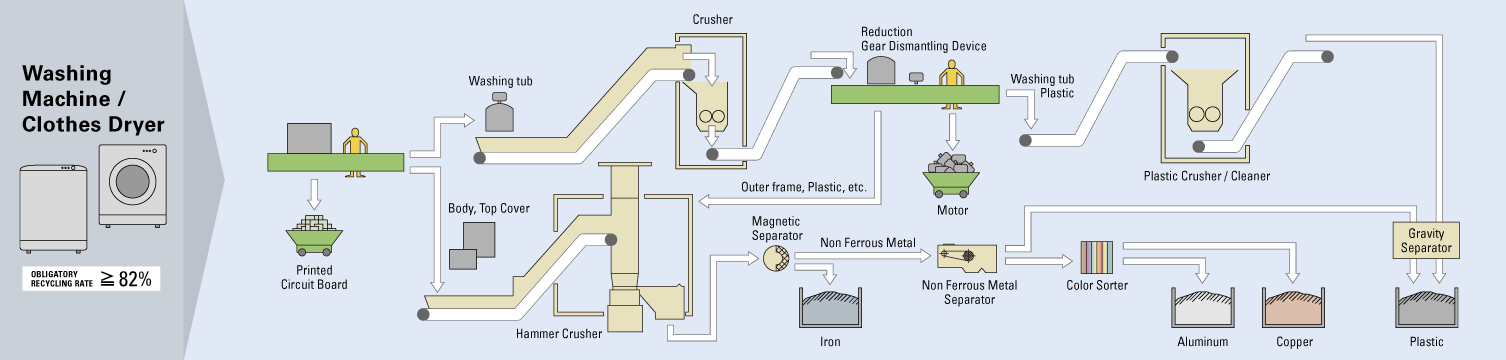

Recycling Flow: Washing Machine

①Collect the printed circuit board. ②Roughly crush the washing tub with a crusher and collect the motor. ③Washing tub plastic is crushed and recovered. ④Other crushed items in the washing tub, outer frame and top cover are put into a crusher. ⑤Recovered as iron, copper, aluminum, plastic, etc. by magnetic separation, non ferrous metal separation and color sorting.

Points of recycling

There are two types of washing machines, vertical type and drum type, and the structure of the drum type is often more complicated than the vertical type, and it takes time to dismantle manually. The printed circuit board and motor are manually disassembled and collected. Other than these, various metals and plastics are recovered through mechanical crushing and sorting using the characteristics of the material.

Main recovered resources

Manual dismantling process: Printed Circuit Board, Motor, etc.

Crushing / Separation process: Iron, Copper, Aluminum, Plastic, etc.